Home / Layout solutions

Layout solutions

For the past twenty years, MPBS has been equipped with machine lines that allow for custom work on manufactured panels.

Equipped with the latest technology, these lines offer layout solutions in line with market developments.

Custom work

Our different types of panels lend themselves to several machining possibilities for the production of furniture components, such as cutting, drilling, machining, 3D, grooving, straight and curved edge banding according to the demand of our customers, this activity is based on

1- Design office

Considered as a strategic link in the process and enabling us to deduct and optimize the technical needs of our customers

2- Panel Saw

Allowing rectangular cutting, while ensuring dimensional accuracy and edge straightness.

3- Edge banding machine

Performing the gluing of PVC, acrylic or veneer edges in different thicknesses with an unrivaled finish and protection thanks to the PUR glue of the panels against humidity and temperature

4- Drilling center

For grooves and various holes relating to mounting accessories

5- Machining center

For curvilinear cutting, engraving and routing

6- Packaging

In bubble wrap or polyethylene on pallet or in carton according to customer requirements

Furniture kit

A concept aimed at improving your competitiveness by outsourcing your production;

This type of service provides our clients with control and flexibility in their production and sales processes.

Whether it’s a cabinet or facade, a kitchen or a dressing room, a wide range of choices is available for supports or decors, resulting in a multitude of advantages on various levels:

- Reduced lead times and eliminated waste.

- Cost control and their impact on the final product.

- Flexibility in the face of constant market changes and inventory adjustment.

- Market orientation by focusing your efforts on research, innovation and marketing.

Edge banding

In order to guarantee an impeccable finish to its product, MPBS presents its respective edge coverings for its entire range of products.

Pvc

For the melamine range in thicknesses 0.4/0.8/1 and 2mm widths 22-25-35-45 and 60mm.

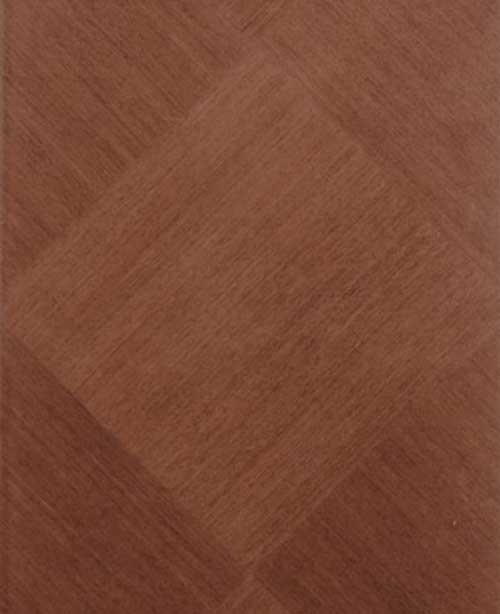

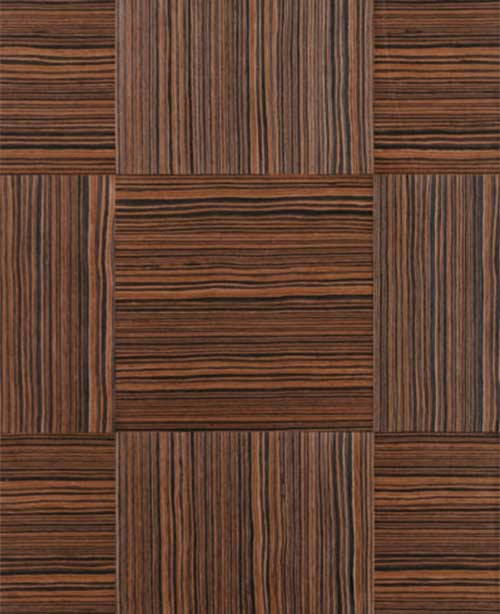

Wood

Available for the veneered range in thicknesses of 0.6 and 2mm, widths of 22-25-35-45 and 60mm.

Acrylic

Covering the range of acrylic panels with two finishes; "uni" and "duo" in 1mm thickness and 23mm width

Endgrain

"Reverse rowing": available for the synchronized panel in 1mm thickness and 22 or 44mm widths.

Door opening

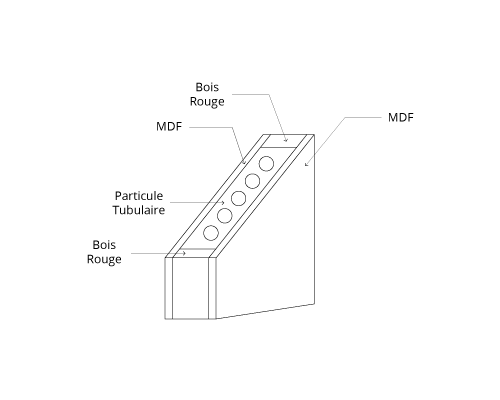

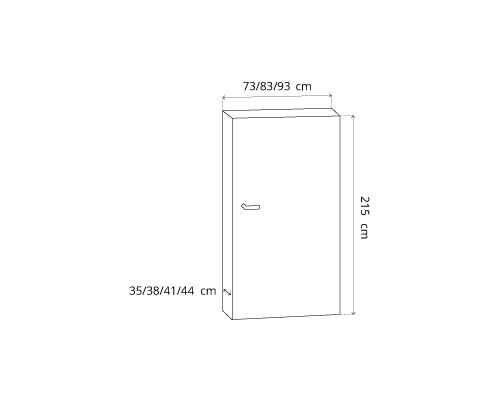

MPBS offers you its range of door openings, which represents the moving part of the door block, made up of two MDF supports as facing having a tubular particle board as interior and reinforced by uprights and crosspieces in red wood.